Titanium is most likely to play more important role in electro chemical applications. Its excellent properties such as low density, high mechanical strength and good corrosion resistance give it many advantages.

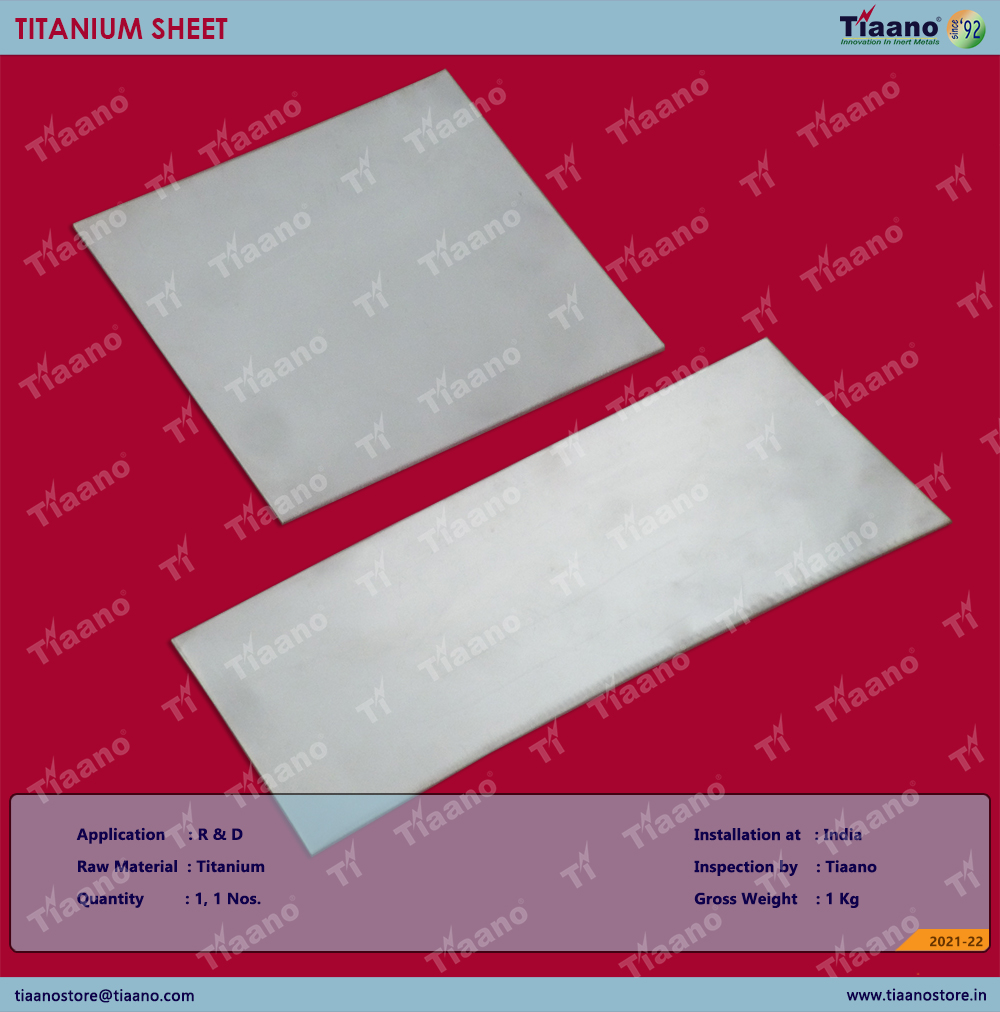

Tiaano is a known manufacturer and exporter of Titanium Gr 1 Sheets and Plates also Titanium anodes and cathodes. Titanium Gr 1 Plates is the most commonly used Titanium worldwide and is the most commonly used alloy in the oilfield, where this alpha-beta alloy is also called as the workhorse alloy of the titanium industry.

Titanium Sheet and Plate Specifications:-

Specifications : ASTM / ASME SB265

Size: Max. 2000 mm

Thickness: Min.0.5 mm to 20 mm

Titanium is an element (chemical symbol Ti, atomic number 22) with a low density and strong durability. It is a strong, lustrous, corrosion-resistant transition metal with a silver color. The two most useful properties of the metal form are corrosion resistance and the highest strength-to-weight ratio of any metal.

Titanium is 30% stronger than steel, but is nearly 50% lighter. Titanium is 60% heavier than aluminum, but twice as strong. Titanium has excellent strength retention to 1,000 degrees Fahrenheit. Titanium’s high corrosion resistance is also a valuable characteristic; as when exposed to the atmosphere, titanium forms a tight, tenacious oxide film that resists many corrosive materials, particularly salt water.

Here are 5 uses for titanium plates:-

Laptop Computers - laptop manufacturers

Aerospace Industry

Architecture and Art - buildings and sculptures

Armor and protection applications